Thermal Transfer Ribbons - What are they?

Internet Labels Thermal Transfer Ribbons are made up of between 2 layers and 4 layers and over three grades, Wax, Wax/Resin & Resin, We offer ribbons for both Flathead and Near Edge printhead systems. Ribbons for these two configurations are different but may use the same grades. Both types work by transferring heat from the printhead to the ribbon which transfers the ink onto the face of the label. Internet Labels supplies as standard wax ribbons as this offers the broadest range of general use. The other types of ribbon are available to order. All Internet Labels ribbons have a special low friction back coating helping to extend the life of your printhead, reducing the frequency of replacement of this expensive component. They are produced using an environmentally friendly solvent free process saving you an average of 365g of CO2* when compared to conventional production methods.

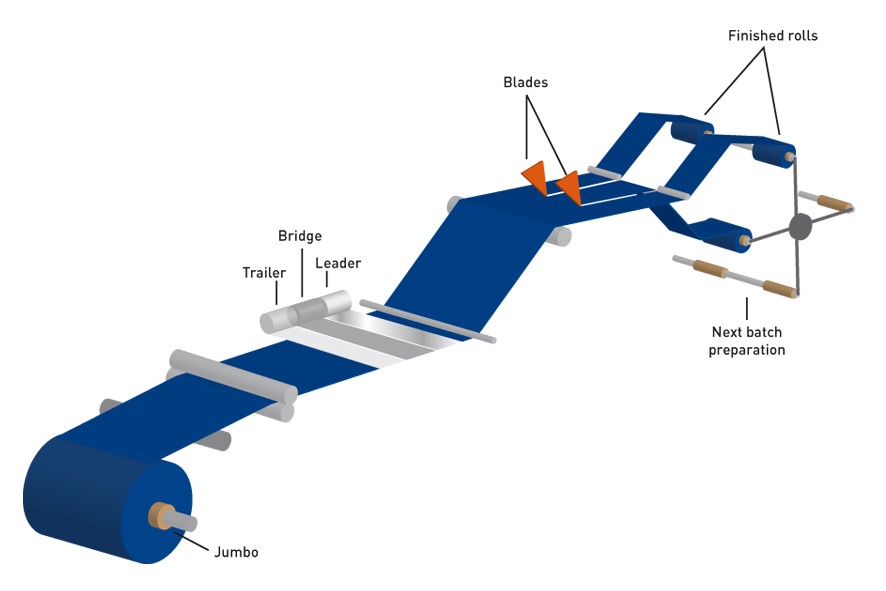

Converting a jumbo roll into printer compatible single ribbons

*Calculated for a roll with average market dimensions

Flathead or Near Edge – What does this mean?

The vast majority of thermal printers use a flathead print system. In flathead printing the printhead is horizontal with the heating elements in the centre of the printhead. As the ribbon passes over the printhead heating elements, the ink is transferred from the ribbon to the label to form the required barcode or text. After printing, the ribbon and label are fed towards the front of the printer, where they are separated and the ribbon wound onto the rewind spindle.

In Near Edge printing the printhead is angled approximately 45° with the heating elements at the edge of the printhead. The label only comes into contact with the ribbon briefly as it passes under the printhead heating elements. This requires faster ink release and therefore a different ribbon formulation which limits near edge ribbon grades to wax/resin and resin.